Going back to natural fibers, is it optional or a must? 2021-03-09 08:23:26

Going back to natural fibers, is it optional or a must?

By: InTexive Consulting Egypt

Based on recent article of Intexive consulting Egypt in the International Fiber Journal https://fiberjournal.com/reversing-the-shift-back-to-natural-fibers/

Once upon a time, there were only natural fibers; in fact, that is not very long time ago! That said, synthetic fibers, such as polyester and nylon have been around since the 1930s, and in the 1980s synthetic fibers started surpassing natural fibers in market share.

Most synthetic fibers were developed from their early conception to mimic their natural counterparts. Those synthetic fibers initially were extruded into continuous smooth filaments, which resembled silk. Later, fiber-bulking technologies were introduced to give a texture to those filaments, so that they would become similar to cotton and wool. Synthetic fibers are engineered fibers, and their properties could be tailored by varying their cross-sectional shape, fineness, crimp, staple length, luster and other parameters. Their versatility and price-performance ratio allowed them to substitute for natural fibers in almost every application. Moreover, their manufacturing processes far surpassed the speed and capacities of processing natural fibers.

As the world developed a reliance on synthetic fibers, some negative consequences became evident, such as ever-depleting oil resources and the problem of microplastics in the oceans due to shedding from synthetic clothing during laundering. In addition, plastic fibers posed environmental issues at their end-of-life, and showed a significant overall carbon footprint.

Challenges facing natural fibers

Lately, many voices have appeared demanding the industry to shift back to natural and sustainable fibers. Practically, this is not possible with the current conditions, because the world demand of textile fibers has reached around 100 million tons in 2020, and natural fibers contribute to only 35% of this demand, while the other 65% is fulfilled by manmade fibers. In fact, one of the main reasons that forced the industry to shift to synthetic fibers, was to bridge the gap between the increasing demand for textile fibers and the limited supply of natural fibers. Hence, to reverse this shift back to natural fibers, the industry must increase the biodiversity of fiber sources, explore new sources of natural fibers and revive the old forgotten ones.

There are several challenges associated with shifting back to natural fibers, including;

- Limited supply – Today, the number of live fiber-animals and areas cultivated with fiber-crops are not sufficient to produce the 100 million tons demand of textile fibers. And in many cases, it is not possible to expand the cultivated areas of those fiber crops because of the competition with food production and deforestation.

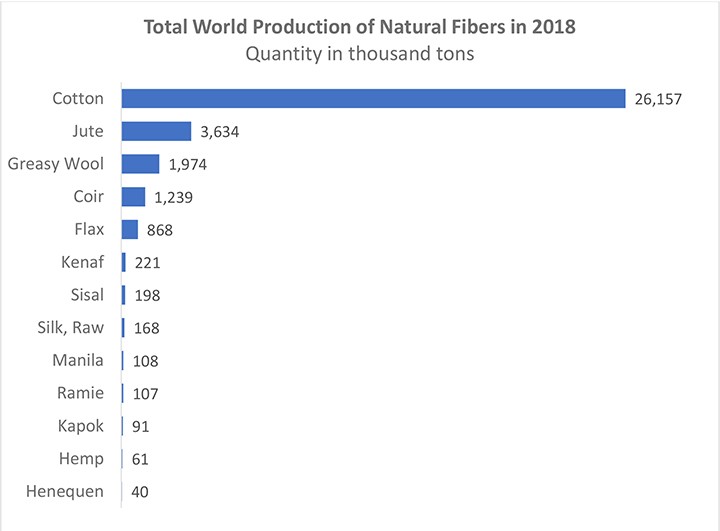

- Lack of biodiversity - The world production of natural fibers is heavily reliant on cotton, which accounts to more than 75% of the total production, followed by Jute 10% and wool 5.6%, whereas the rest of the natural fibers account for less than 9%. This is a big risk, and it was evident in 2010 when the flood hit Pakistan, the fourth largest producer of cotton, and destroyed the entire crop, which severely affected the entire cotton supply chain.

- Machine manufacturers focus on commodity – One of the biggest challenges with using new sources of natural fibers, is processing it into a legal textile form. This is because the textile machine manufacturers develop processing lines only for commodity natural fibers, such as cotton, wool and flax. Whereas, the processing of the other natural fibers suffers from extensive manual operations and utilize semi-automated primitive machinery.

- Climate change – Climate change has negatively impacted the production of natural fibers; this is due to water scarcity, desertification, and global warming. All of which had undesirable consequences on livestock, and other climate-sensitive fiber crops.

Figure 1. There is a lack of biodiversity in natural fibers, the world production is heavily reliant on cotton, which accounts to more than 75% of the total production. Source: Intexive calculations based on FAOSTAT statistics

Biorefining of natural fiber sources

So, the question remains, did scientists, technologists and agriculturalists tap into every possible source of natural fibers? No, because there are only few sources of natural fibers where the fibers are obvious, such as hair and lint, while, there are many other sources where the fibers are not visible and hidden inside the plant, for instance. These fibers require what is known as biorefining of natural resources, which is the sustainable processing of biomass into a spectrum of marketable bio-based products and bioenergy. Most crops result in primary products, which are the fruits and secondary products in the form of lignocellulosic biomass. This lignocellulosic biomass can be used in biorefining for extracting several biobased materials, including fibers. This biomass benefits from high feedstock availability, moderate costs and no direct competition with food production. The main constituents of this biomass are cellulose, lignin and hemicellulose, which can be separated using different methods and further processed into a wide range of products.

Cellulose fibers, which are present in the form of long fibers inside the biomass can be extracted and used as a textile fiber. This approach has been applied to several new fibers obtained from agriculture byproducts, such as extracting fibers from the banana pseudo stem, and from pineapple leaves. Moreover, recently a new fiber has been extracted from the byproducts of pruning of date palms, such as the frond and fruit stalks. This fiber is said to have estimated global annual availability of up to 1 million tons, and the development team claims that the extraction technology could be applied for extracting textile fibers from byproducts of other palm species, such as oil palm, coconut palm and sugar palm. In addition, the byproducts of other agriculture crops, such as sorghum, can be extracted. This approach contributes to the development of the circular bioeconomy of the future and may significantly increase the biodiversity of fiber crops and expand the palette of natural fibers, resulting in larger, more sustainable and economical supply, which would aid in the industry’s shift back to natural fibers.

Figure 2. Biorefining of lignocellulosic biomass from the byproducts of pruning of date palms into natural textile fiber called PalmFil. Photo: Intexive consulting