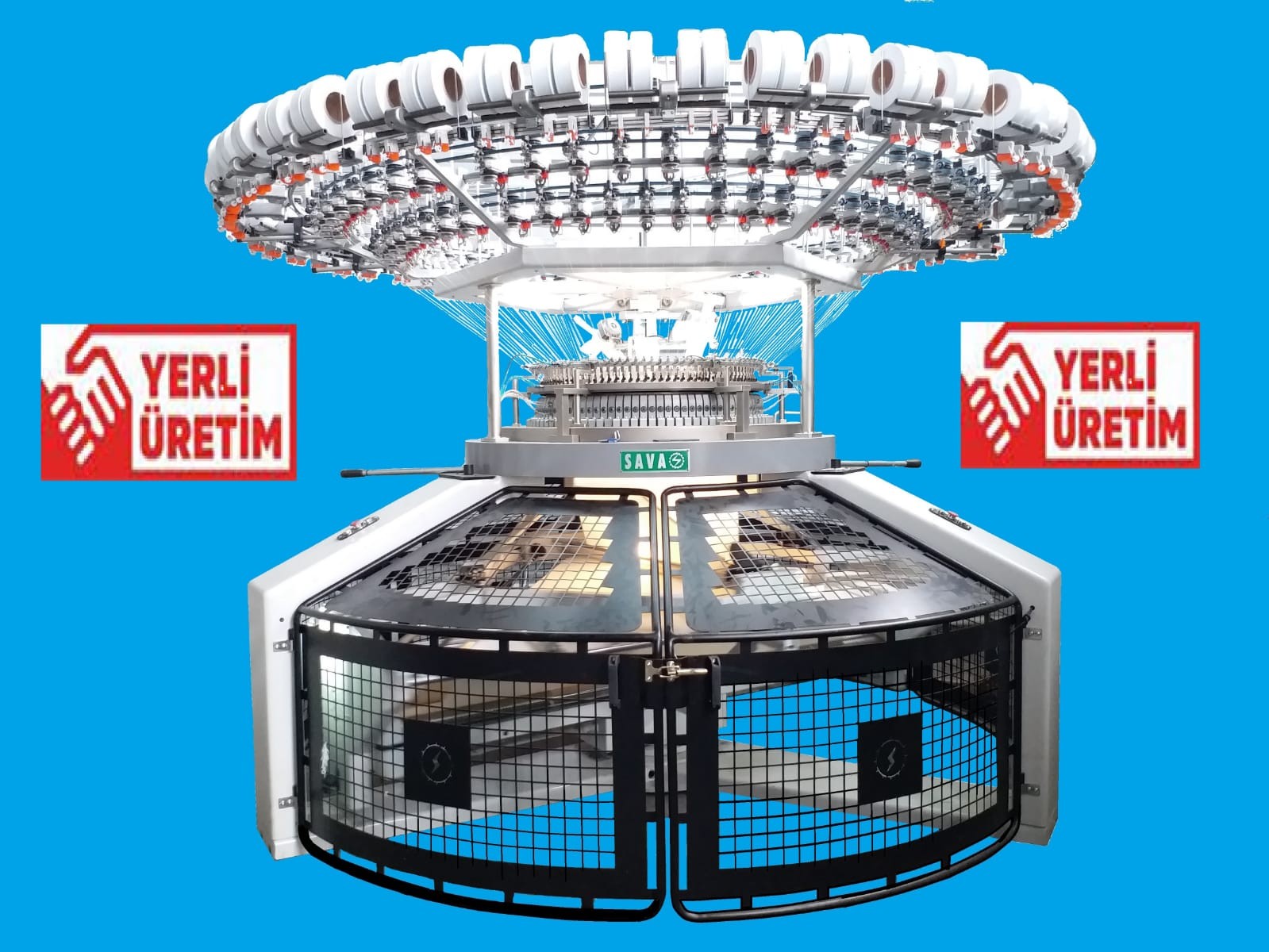

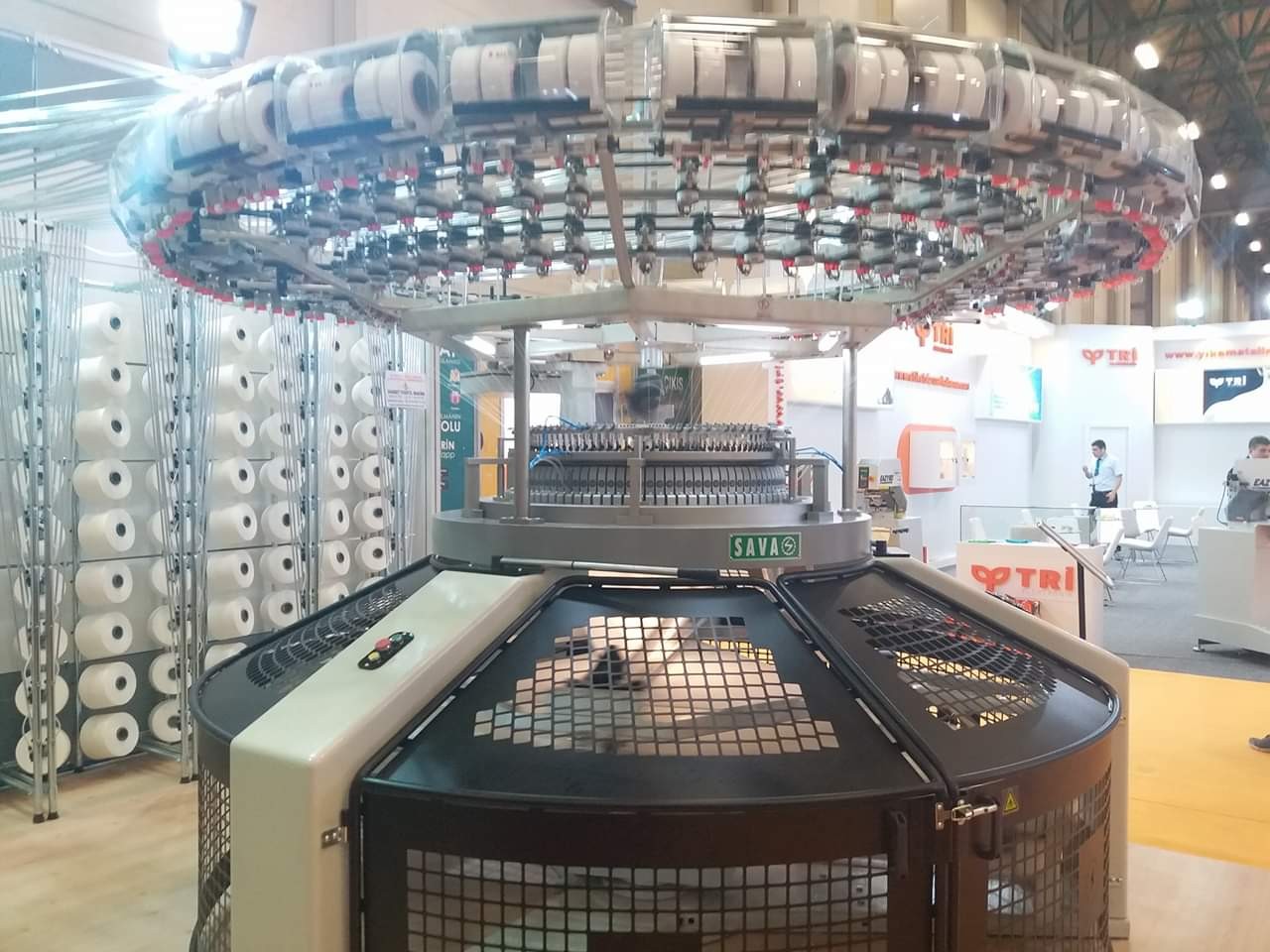

SAVA; Turkey's First Manufacturer of Circular Knitting Machine 2020-02-12 08:59:47

SAVA; Turkey's First Manufacturer of Circular Knitting Machine

Mr. Ahmet YILMAZ /Sava Machinery Co-Founder

SAVA, Turkey's only manufacturer of single circular knitting machines, says: "Each knitting manufacturer must have a domestic machine." Ahmet Yılmaz, one of the partners of Sava Machinery who says that they "Our industrialists have the priority of local machines."

You are a company that meets the need of knitting machine which is one of the most serious needs of knitting sector. Most importantly, you can do this in Turkey. In this context, could you introduce yourself to our readers more closely?

We serve the textile sector with 25 years of experience. Five years ago, we established this company by establishing Sava Machinery. We were manufacturing machinery in the previous companies, but we got professionalism with Sava. We were able to remove the machine as a real machine and offer it to the customer's service with Sava. Machine become a real machine in Sava. Sava, Turkey also makes the production of hives for all of the circular knitting machines. This part, which works as a housing for the platinum and needle , is the lifeblood of the machine. Hive was made first by Sava Machinery in Turkey. We have been continuing our production of hive for five years. We have brought our hives to a very good point. We can make beautiful hives. There is no other company in Turkey that produces hives in addition to Sava.

Which of knitting machines are you assertive?

We are very successful in the single jersey, three thread, interlock and ribbon groups of circular knitting machines. At the moment, I would like to mention a product that we are preparing to introduce to the market, in order to inform our sector: We make a special machine that can roll a high lap, 150 kg. We are talking about a machine that can roll up to 150 kilograms of fabric at the same time in 35 rounds. There is no other company in Turkey that can manufacture it. Now the product is in our own testing phase. In fact, one of our customers was tried as a high tour for six months, and thankfully a very productive product appeared. Hopefully we are planning to launch this at the beginning of 2019. Apart from that, we have very good three thread machines. We have three thread machines that can rotate in 25 rounds, have no vanisy faults, and can deliver around 500 kilograms. There is no other machine in the market that can catch this yield. At the end of the day, we are compared to the Europeans in terms of quality. More precisely, the sector compares us with Europeans in terms of quality, but it is not possible to compare our price with the Europeans!

Europeans play a very important role in competing knitting machines. And you have competitors in Far East. What would you like to say about this competition?

Actually, our main competitor is the Far East. Our people want our products to be as good as Europeans, and expect our prices would be lower than the Far East. Unfortunately, countries of Far East China, Taiwan, Singapore are our bigger rivals because people care about prices at this stage. We are not bothered by the Europeans. If we are alone with Europeans in this market, we can get a better place for ourselves.

As Sava Machinery, how are your prices when compared to Far Eastern companies?

Sometimes we have offered with the price of the Far East, sometimes over 10-20 percent of the far east. But we never gave a machine at a European price, we couldn't, and we can’t. Three thread machines from Taiwan are sold at $ 33-34 thousand. We can offer the same machine here for $ 28,000. For the same machine, I can easily say that our machine gives 20% more product within 24 hours. While 350 kilos of products is taken from foreign machines, domestic and national machines provide 500 kilos of products.

Why doesn't the Turkish knitter choose you in spite of these conditions?

Our knitter is a little conservative. People who don't give up on their habits. The machines we are talking about are brands in Turkey market for 20-25 years. These are companies that have acquired a customer base in the market in time. So they reached a good position. As Sava Machinery we need some more time to prove ourselves. Maybe we should give some importance to the advertisement, maybe we need to talk with people and explain our features and differences. Our people are unfortunately remain distant against domestic machines. Today, a knitting master who finds a mistake in a European or Far Eastern machine, confronts his boss with pride, says he corrected the mistake. When he meet the same distress in our machine, he never touches and says "this man's machine is useless." We, unfortunately, could not gain the trust of our people. There is a psychological prejudice, and unfortunately we cannot break it.

When you have problems with these products, how do you produce solutions as Sava?

One of the best topics is service. Because we are here, we are the people of this country; so we are obliged to give the service faster than a stranger. Technical service is also very important while buying a product.

Turkish textile industry was rapidly industrializing in the years and it managed to do so with machines from Europe. While the number of industrialists increased at a tremendous rate, the Turkish machinery sector did not make a progress and could not produce alternatives. Far east recognized textile sector later than us quickly produced its own machines, before completing the gap in the interior, then turned to export. Why couldn't we? What would you say about this issue?

The Chinese state is able to evaluate such opportunities very well. The Chinese state supports its producer and its people. We have also made occasional trade with China. The Chinese government says: I'm going to pay you 10 to 20 percent of the invoice amount for the export. After the export, you receive the receipt and you receive 10-20% of the money from the Government. A company which exports100 thousand dollars in a textile machine applies the state and get 20 thousand dollars. I mean, their sales prices reach 120 thousand dollars. This business started with 20 percent, now we see it decreased to10 percent. But today, these companies, even if they sell the cost of goods, are profitable for 10 percentage. Our profit margins are already at this level. We, as machine manufacturers, expect support from the State, but rather than us, we want the textile manufacturers, which we sell our product, to support. We want exceptions to the local machine area manufacturer. This can be interest-free loan, long-term credit, interest-free loan. The domestic manufacturer has to have a really serious advantage to choose our machine. These people are not people who take cash out of their pocket and buy machines for $ 1 million. As a result, the people who work with bank, leasing, buy machine abroad and pay interest. I wish our state could say to the local machine buyers that: "24 months of installments are now extended to 36 months." In this way, we develop ourselves, make R & D, bring out new products, and turn to export. However, there must be a regular flow when doing all of this.

Does Sava benefit from R & D supports?

Obviously we didn't pursue them much. In the past we had once received such support. But as I said, we want to support the group we sell instead of supporting us. The knitter should be supported so they would prefer our machine.

How many people work in Sava Machinery? Do you have an export target?

We have a team of about 20 people. From time to time this decreases or increases. We have just started to work on export. We have studies on Uzbekistan, India and the Czech Republic. Hopefully, it will soon come to an end. We will exhibit our brand in various countries around the world. We started to work in the middle of 2018 and I think we will take the fruit in 2019.

What would you like to share with our knitting industry through our magazine?

We have a motto like this: In our country, we must say that every business must have a domestic machine. You get it, you try, and tell us if you have a problem. You look at the service, the tests, you use; If you are satisfied, you will buy more. If you are not satisfied you will not buy. No one is forced to sell anyone. To get the second one of a product, you really need to be satisfied with that product. This is what we say to our knitting friends: If each circular knitting machine is run in a domestic manufacturer, both our work will be easier and they will guide us. I'm sure they’ll follow performance of machine closely. Our manufacturers may not show interest to our machines as Europe and Far East brands. I'm not complaining about that either. May they tell us about our shortcomings, advantageousness of us. And we can develop ourselves within the framework of these needs.

It's hard to sell the first machine probably. Did you sell the second machine to the same company?

We still sell machines to the company we sold ten years ago. In the company where we first sold machine, today we have around 10 machines working. We are proud of the fact that they multiply the number of our machines in their own company. We can sell our second machine much more easily, because people's prejudice is breaking, because our machine is an efficient and successful machine.

The last 3-4 months was very difficult in terms of textiles. What is the situation from a machine manufacturer's window?

The chain breaks down from the weak link when forced. Of course there will be bankrupting companies but I believe that knitting sector in Turkey will earn more money for many years. I sincerely believe that this sector will be in demand. Every crisis is actually an opportunity. As a result, our country no longer sells goods only to Europe. We are a country that can export to every country of the world, including China. If we look at the eyes of a knitter today, a kilogram of sub - manufacturing in China is around 1 TL 40 qurush. In Turkey, the same price is around 1 to 1.10 TL. But how long will the knitter stand on this number, and this is another important question, I can't comment anything. But Europeans began to return Turkey from China. The figure was convenient, Market is closer. In fact, Turkey can turn this crisis into a fruitful opportunity.

Does Sava have competitors in Turkey?

Sava has no Turkish competitors. There are some domestic companies engaged in knitting machine but Sava Machinery does not have a competitor which has wide range of products. Sava does not only offers single jersey machine, it is able to offer three thread or ribbons. Sava has no competitor. There is no other company in Turkey that makes hives. Our biggest problem is the Far East. Some of the representative firms can import low-price hives from the Far East.

Turkey cannot produce domestic needles in the knitting sector. What is the reason for this?

Turkey is a textile paradise, but only in terms of taking the machine and turning it into a fabric, unfortunately, not in the sense of making machinery. Turkey cannot see this. If the hive could be produced 20 years ago in Turkey, our work would be much easier. Needles are a bit more difficult to produce. And I wish success to my colleagues in Turkey for needle investment. We had several difficulties to promote our hive, the knitter will carefully approach the domestic needle. The needle is a very strategic product. A set consists of three thousand needles. People receive a minimum of 500 kilograms of fabric from a machine in 24 hours. The fabric has a very high error return rate. Needle is a distressed product. You produce it and give the knitters free; they will affix the needle after considering a lot. It is not difficult to manufacture, but it is a difficult to promote and accustom the people.

As a machinery manufacturer your raw material is steel too. How do you meet your steel needs?

We have to talk in dollars when we market our machines. Because our raw materials are connected to the foreign exchange. Five months ago, today's prices have changed almost half. For a machine that could be sold by 100 thousand TL a year ago, now we can offer our customer 90 thousand TL. But our opponents also offer prices in dollars, so this does not affect us too much. But, of course, if our raw materials were native, we would be more competitive if we could buy it in TL.

What level of prices you have when you compare with your European competitors?

We're half cheaper. In our people, unfortunately, there is a foreign admiration. We cannot prevent this unless we change this perception in our people. Since we were children, we celebrated the Native Goods Week in schools, but we have to teach our new generation what the real meaning of this is. We need to say "Local first " There could be better products, of course. We are a country that supported South Korea 50 years ago. A wrecked, sunken country is now in a good condition now. We should consider about it. They have many brands worldwide. This is because the people of South Korea is a very nationalist people. I traveled to South Korea, I did not see one European car. Everybody was riding a Korean car. Everybody was using their own phone in South Korea. They are so nationalist people because they buy the second hand machines in Turkey. Everybody becomes a nationalist while dying, but we have to be a nationalist in this sense.

What you want to emphasize with our magazine?

My knitter friends! Please don't be afraid of the domestic machine. Try. Let's give a machine to your company. Test it, run it, look at its efficiency, and decide the next step by trying our product. Please do not approach us with prejudice.